Engis has developed a Complete Process Solution for Indium Phosphide (InP) wafer processing:

The HVG-250/300 series Vertical Grinding Machine combined with Engis MAD Grinding Wheels can achieve a superior surface finish on InP wafers to reduce or even eliminate loose abrasive lapping steps. The machine can be customized to your needs:

Indium phosphide wafer lapping can minimize the burden on the final CMP step by creating a low Ra surface finish while maintaining superior flatness. This can be achieved in one or two steps, using successively softer Hyprez composite lap plates and finer Hyprez diamond slurry. The EJW-910 series is 4-6” InP wafer compatible, with batch processing for high efficiency.

Engis Products:

.

.

For CMP of Indium Phosphide, safety needs to be a top concern to avoid the formation of phosphene gas during polishing, exposing workers to a toxic environment. Engis has formulated a 2-part CMP slurry specifically for use with InP substrates which contains chemistry to prevent the formation of phosphene gas. This formula achieves a damage free, low roughness surface finish following lapping or fine grinding.

Engis Products

.

.

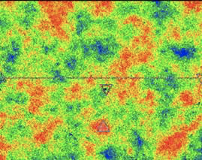

Post CMP surface finish: 0.3 nm Ra

Figure 1:Zygo Optical Profilemeter image @20X. Figure 2: Zygo Optical Profilometer scan @ 200X