Your Key to Ultra-Precision Lapping & Polishing

Maintaining a flat and evenly textured composite lap plate is critical for stable lapping performance. Traditionally this is achieved with a diamond plated conditioning ring, requiring a high level of operator experience and skill. To improve this process, Engis has engineered a solution that helps take the ‘art’ out of lapping, the Facing/Grooving Device.

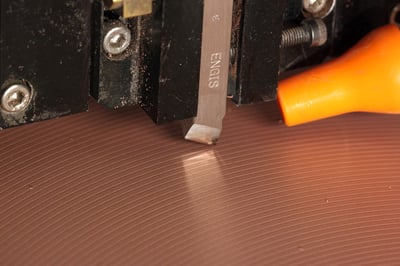

Using a diamond tool bit, this innovative device removes the top layer of the composite plate, making it flat to within microns. A groove pattern can be machined in a second pass. It is even possible to create a tapered plate to produce slightly convex/concave surfaces. When the device is not in use, it retracts out of the work zone.

Plate Facing Advantages:

With predictable plate surface topography, groove pattern and controlled velocity and pressure, the entire lapping process becomes easier to manage and your results are more repeatable. Also, this unit is operator-friendly and eliminates the strain of lifting conditioning rings onto the plate.

The facing/grooving device is an option that can be added to most Hyprez lapping machines at the time the machine is ordered.

|

|

|

Having Problems with Variable Lapping Rates? Control Plate Flatness and Texture The lapping plate is a key component of any lapping system and is often overlooked as an important variable.

COLORED HIGHLIGHTS REPRESENT PLATE BEARING AREA

|

|