An efficient lapping operation requires the selection of a proper lap plate. This selection is guided by the process objective (stock removal, fine finish), the material being lapped, and the diamond size/type used in the lapping slurry.

An efficient lapping operation requires the selection of a proper lap plate. This selection is guided by the process objective (stock removal, fine finish), the material being lapped, and the diamond size/type used in the lapping slurry.

A composite lap plate is comprised of metal or ceramic particles in a resin matrix, allowing for efficient charging of diamond abrasive particles into the plate. This charged composite plate can significantly reduce process times and achieve a finer surface finish, often in a single step. A composite plate is also well suited for a facing device, taking the guess work out of flatness and texture control.

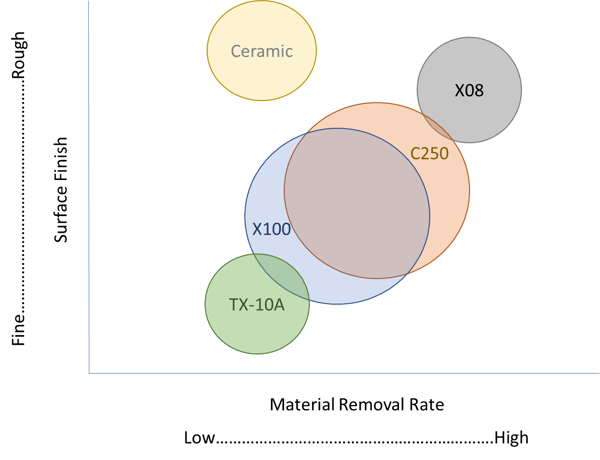

Hyprez® X08

Composite Iron plate with most aggressive stock removal; good alternative to cast iron

Hyprez®C250

Composite copper plate; our most universal plate, often used for single step operations

Hyprez®X100

Composite aluminum plate; good substitute for C250 when copper contamination is a concern

Hyprez® TX-10A

Composite tin plate; very fine finish, minimizes or replaces pad polishing to maintain flatness

Hyprez® HY Ceramic

Composite ceramic plate; used when metal free processing is required

Hyprez® Composite Plate Configurations: