If you are manufacturing bonded superabrasive tools or grinding wheels, the surface cleanliness of the diamond and CBN particles is a key factor in achieving a strong bond regardless if you are utilizing a mechanical or electrochemical process. If your manufacturing procedure calls for utilizing diamond slurries or compounds, the surface cleanliness of diamond particles themselves is critical to achieving good particle dispersion. And, if you are manufacturing PCD or PCBN blanks, the cleanliness of the surface of diamond and CBN particles is of paramount importance towards achieving good high pressure-high temperature sintering.

The manufacturing of micron superabrasive powders involves chemical processes that are meant to remove all inorganic contaminants (metallic and ceramic residues) from the end product. During these processes, the micron powder is exposed to reaction with inorganic acids and salts. It is during the classification or grading stage, that the micronizer may “contaminate” the powder through the introduction of certain chemical substances (surfactants and dispersants) which facilitate particle dispersion and thus, classification. These chemical substances that are absorbed to the particle surface, if not properly removed afterwards, account for surface contamination.

The task of achieving high surface purity is a very difficult one, particularly in the sub micron size range, knowing the finer the size of the powder, the higher the surface area. At Engis, we have extensive experience along with the proper equipment and processes to ensure that the powders that we supply to you are 100% contaminant free.

Technique and Equipment

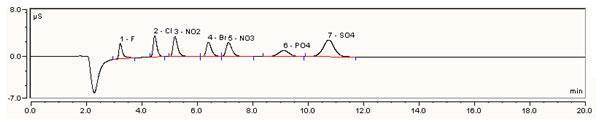

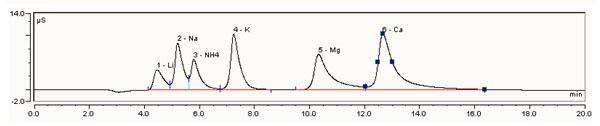

We utilize Ion Chromatography (IC) to conduct quantitative analysis of the presence and concentration of ionic contaminants (anions and cations) extracted from the surface of the diamond particles.