.png)

The HVG-250/300 series Vertical Grinding Machine combined with Engis MAD Grinding Wheels can achieve a superior surface finish on silicon carbide wafers to reduce or even eliminate loose abrasive lapping steps. The machine can be customized to your needs:

Silicon carbide wafer lapping can minimize the burden on the final CMP step by creating a low Ra surface finish while maintaining superior flatness. This can be achieved in one or two steps, using successively softer lap plates and finer diamond slurry. The EJW-910 series is 6” SiC wafer compatible, with batch processing for efficiency.

.

.

.

.

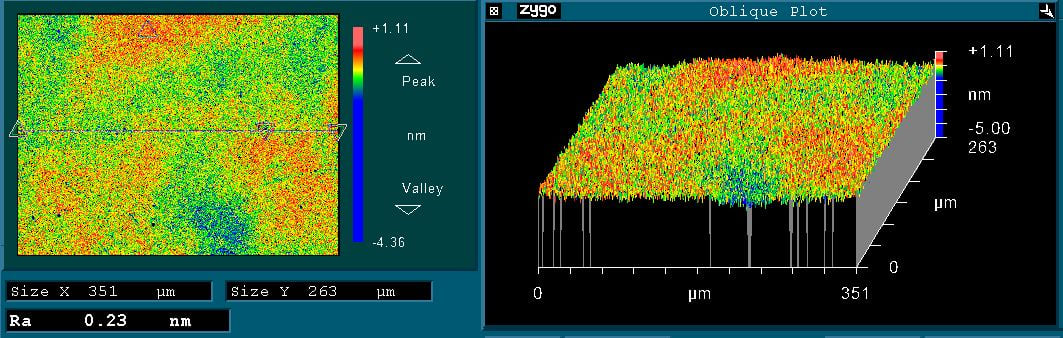

Engis has developed a slurry and pad combination specifically designed for the needs of Epi-Ready Silicon Carbide CMP, achieving a damage free, low roughness surface finish in a single, high-throughput step.

.

.