End Repeatability and Accuracy Challenges

For years Engis has worked successfully with manufacturers of handguns, as well as sporting and military rifles, to improve product consistency, reliability and lower costs in both the high and low production and finishing of various firearms components.

ENGIS ADVANTAGE (ENGIS SINGLE-PASS HONING SOLUTION):

MACHINE: CNC Controlled, Multi-Spindle Honing Machine

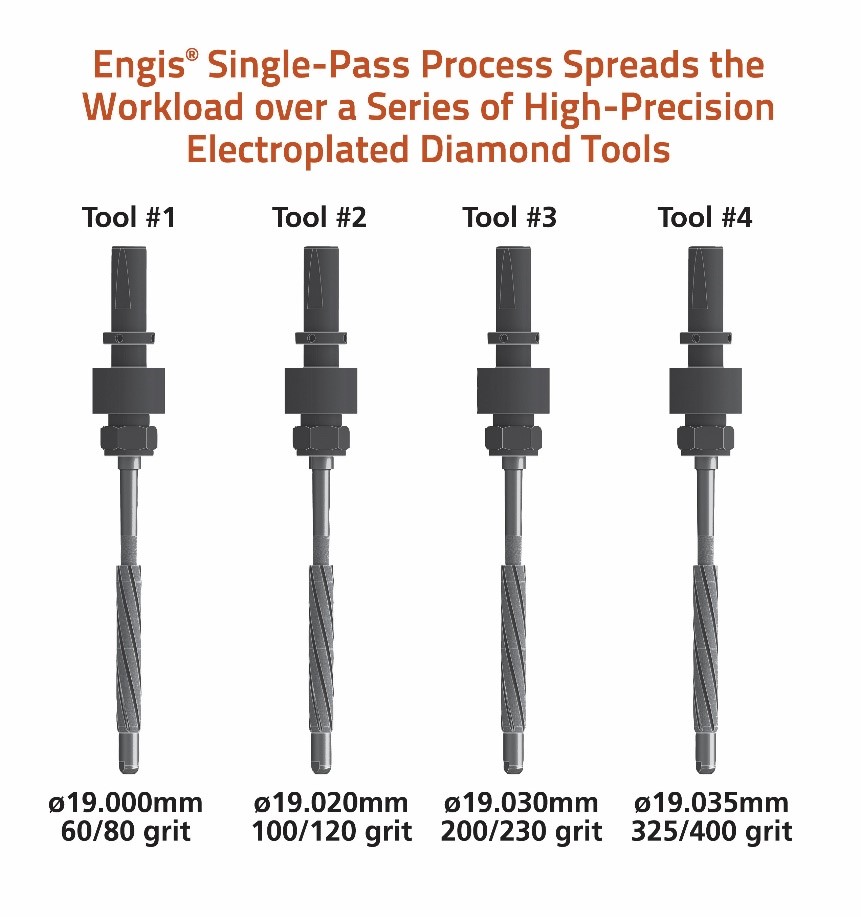

TOOLING: “Single-Pass Hone”, Highly Repeatable, Diamond Plated Adjustable Abrasive

BORE DIAMETER: 0.002mm Range

ROUNDNESS: < 0.001mm

SURFACE FINISH: <0.1 Ra

PRODUCTION RATE: 20 (350mm long )Barrels per Hour

MACHINE EFFICIENCY: 95% Uptime

TOOL CHANGE-OVER: Predictable 15 minutes every 20,000 Parts

OPERATOR SKILL RQD: Load/Unload Parts, Push Cycle Start Button, Adjust Tools